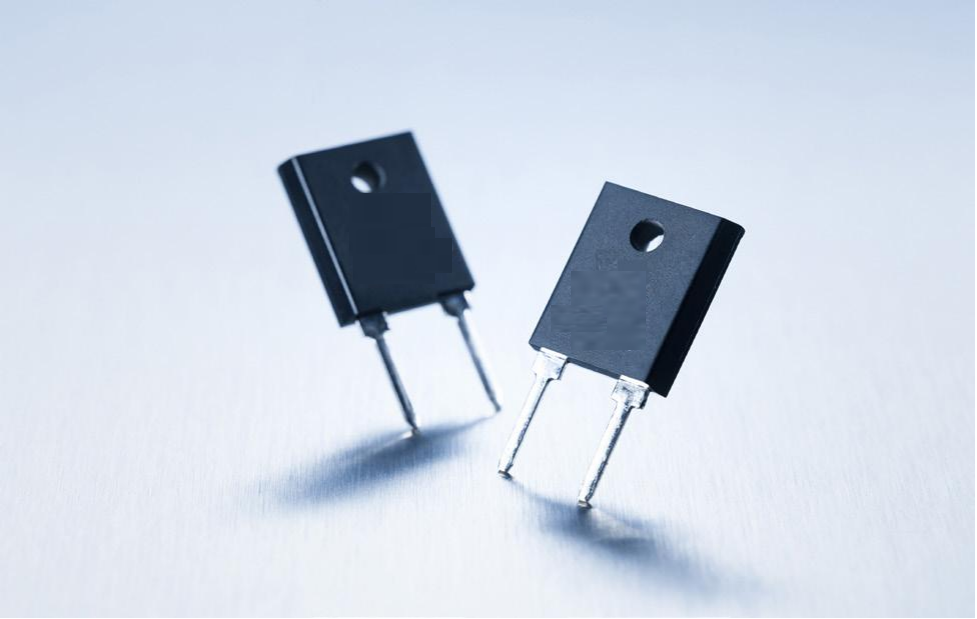

Ukuya kwi-247 i-resistor yamandla ye-EAK yeenjineli zokuyila ukubonelela ngepakethi ezinzileyo yohlobo lwe-transistor yezixhobo ezixhathisa amandla aphezulu, amandla yi-100W-150W

Ezi zixhasi zenzelwe izicelo ezifuna ukuchaneka kunye nokuzinza.I-resistor iyilwe nge-alumina ceramic layer eyahlula i-resistor element kwi-plate yokukhwela.

I-Eak ibunjwe TO-247 ifilimu eshinyeneyo yokumelana namandla

Esi sakhiwo sinika ukuxhathisa okuphantsi kakhulu kwe-thermal ngelixa uqinisekisa ukuxhathisa okuphezulu kwe-insulation phakathi kwe-terminal kunye ne-backplane yensimbi.Ngenxa yoko, ezi zixhasi zine-inductance ephantsi kakhulu, ezenza zilungele ukusetyenziswa kwe-high-frequency kunye ne-high-speed pulse applications.

Ukumelana noluhlu ukusuka kwi-0.1Ω ukuya kwi-1 MΩ,Uluhlu lobushushu bokusebenza: -55°C ukuya +175°C.

I-EAK iya kuvelisa izixhobo ezingaphaya kwezi nkcukacha ukuhlangabezana neemfuno zabathengi.Izichasi zamandla ze-EAK zithobela imigangatho ye-ROHS, zisebenzisa i-lead-free termination.

Iimbonakalo:

■ I-100 W amandla okusebenza

■ TO-247 uqwalaselo lwephakheji

■ Ukufakela isikrufu esinye kwenza lula ukuncamathela kwisinki yobushushu

■ Uyilo olungasebenziyo

■ ROHS iyahambelana

■ Izinto eziphathekayo ngokuhambelana ne-UL 94 V-0

I-M3 yokunyusa i-screw kwi-radiator.I-enclosure ebunjiweyo inika ukhuseleko kwaye kulula ukuyifaka.Non-inductive uyilo, umbane wedwa izindlu.

Isicelo:

■Ukumelana netheminali kwi-RF yokukhulisa amandla

■ Umthamo we-pulse wamandla aphantsi, isixhasi segridi kubonelelo lwamandla

■ I-UPS, ii-buffers, izilawuli zombane, izixhasi zokulayisha kunye nokukhupha kwiimonitha zeCRT

Uluhlu lokuchasa:0.05 Ω ≤ 1 MΩ (amanye amaxabiso kwisicelo esikhethekileyo)

Ukunyamezela ukuchasa: ± 1 0% ukuya ± 1%

Umlinganiso wobushushu:≥ 10 Ω: ±50 ppm/°C ebhekiselele kwi-25 °C, ΔR ithathwe +105°C

(enye i-TCR ngesicelo esikhethekileyo samaxabiso aqingqiweyo ohmic)

Umlinganiselo wamandla: 100 W kwi-25°C iqondo lobushushu elisezantsi lehlile ukuya ku-0 W kwi-175°C

Ubuninzi bombane osebenzayo: 350 V , max.500 V ngesicelo esikhethekileyo

Amandla ombane weDielectric: 1,800 V AC

Ukumelana ne-Insulation:> 10 GΩ kwi-1,000 V DC

Amandla e-Dieletric: MIL-STD-202, indlela ye-301 (1,800 V AC, 60 sec.) ΔR< ±(0.15 % + 0.0005 Ω)

Ubomi bomthwalo: MIL-R-39009D 4.8.13, 2,000 iiyure kumandla okalisiweyo, ΔR< ±(1.0 % + 0.0005 Ω)

Ukumelana nokufuma: -10 ° C ukuya +65 ° C, RH > 90 % umjikelo 240 h, ΔR< ±(0.50 % + 0.0005 Ω)

Thermalshock:MIL-STD-202, indlela 107, Cond.F, ΔR = (0.50 % + 0.0005Ω) ubuninzi

Uluhlu lobushushu obusebenzayo:-55°C ukuya +175°C

I-Terminalstrength:MIL-STD-202, indlela ye-211, i-Cond.A (Uvavanyo lokutsalwa) 2.4 N, ΔR = (0.5 % + 0.0005Ω)

Ukungcangcazela, i-frequency ephezulu: i-MIL-STD-202, indlela ye-204, i-Cond.D, ΔR = (0.4 % + 0.0005Ω)

Izinto ezikhokelayo: ikopolo enkonkxiweyo

ITorque:0.7 Nm ukuya ku-0.9 Nm M4 kusetyenziswa isikrufu se-M3 kunye nobuchule bokufaka iwahser yoxinzelelo

Ukumelana nobushushu kwipleyiti yokupholisa:Rth< 1.5 K/W

Ubunzima:~4 g

ISikhokelo seSicelo seRadiator Mounted Power film resistors

Yazi iqondo lobushushu kunye nokalisho lwamandla:

Umzobo 1-ukuqonda ubushushu kunye nokulinganiswa kwamandla

INdibano yezinto zokuqhuba ubushushu:

1,Kukho umsantsa ngenxa yotshintsho kwindawo yokukhwelana phakathi kwephakeji yokuchasa kunye neradiyetha.Ezi voids ziya kunciphisa kakhulu ukusebenza kwesixhobo sohlobo lwe-TO.Ke ngoko, ukusetyenziswa kwezixhobo zokujonga i-thermal ukuzalisa ezi zikhewu zomoya kubaluleke kakhulu.Izinto ezininzi zingasetyenziselwa ukunciphisa ukuxhatshazwa kwe-thermal phakathi kwe-resistor kunye ne-radiator surface.

2,Igrisi ye-silicone ehambisa ubushushu yindibaniselwano yamasuntswana aqhuba ubushushu kunye nolwelo oludityanisiweyo lwenze ukuhambelana okufana noko kwegrisi.Olu lwelo ludla ngokuba yioyile ye-silicone, kodwa ngoku kukho igrisi entle kakhulu “engeyo-silicon” yobushushu.Iiresin ze-silicone ze-Thermally conductive zisetyenziswe iminyaka emininzi kwaye zihlala zinokumelana ne-thermal ephantsi yazo zonke izinto ezikhoyo zokuqhuba i-thermal.

3,Iigesi ezihambisa ubushushu zithatha indawo yesilicone eqhuba ubushushu kwaye ziyafumaneka kubavelisi abaninzi.Ezi pads zinephepha okanye imilo yokusika kwangaphambili kwaye zenzelwe iindidi zeepakethe eziqhelekileyo ezifana ne-TO-220 kunye ne-To-247.I-gasket ye-heat conduction yimpahla ye-spongy, idinga uxinzelelo olufanayo kunye nokusebenza okuqinileyo ukuze kukwazi ukusebenza ngokuqhelekileyo.

Ukukhethwa kwezixhobo zehardware:

I-hardware efanelekileyo yingqwalasela ebaluleke kakhulu kuyilo oluhle lokupholisa.I-hardware kufuneka igcine uxinzelelo oluqinileyo kunye nolunye uhlobo kwisixhobo ngokusebenzisa ibhayisikili ye-thermal ngaphandle kokuphazamisa i-radiator okanye izixhobo.

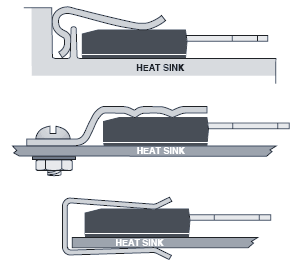

Abaqulunqi abaninzi bakhetha UKUQHAGAMSHA i-DeMint KWI-resistor yamandla KWI-radiator usebenzisa ikliphu yasentwasahlobo endaweni yendibano yesikrufu.Ezi ziqeshana zasentwasahlobo zifumaneka kwinani labenzi ababonelela ngemithombo emininzi eqhelekileyo kunye neeradiyetha ezilungiselelwe ngokukodwa ukunyuswa kwekliphu kwi-TO-220 kunye ne-To-247 iiphakheji.I-clamp yasentwasahlobo ineenzuzo ezininzi ekulula ukuzihlanganisa, kodwa eyona nto iluncedo kakhulu kukuba ihlala isebenzisa awona mandla abalaseleyo kumbindi wesichasi samandla (jonga uMfanekiso 2)

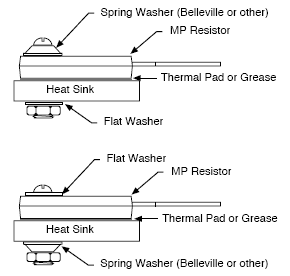

Umzobo we-3-screw kunye ne-washer mounting technique

I-Screw Mounting-belleville okanye i-tapered washers esetyenziswe ngezikrufu yindlela esebenzayo yokudibanisa kwi-radiator.Iiwasha zaseBelleville ziziwasha zasentwasahlobo ezenziwe ngetapered ezenzelwe ukugcina uxinzelelo oluqhubekayo kuluhlu olubanzi lokuphambuka.I-gaskets inokumelana nomjikelezo wexesha elide lobushushu ngaphandle kokutshintsha koxinzelelo.Umzobo 3 ubonisa ezinye zolungelelwaniso lwehardware eqhelekileyo yokunyusela isikrufu sepakethe ye-TO KWIrediyetha.Iiwasha ezingenanto, iiwasha zeenkwenkwezi, kunye neewasha ezininzi zokutshixa azifanele zisetyenziswe endaweni yeewasha zaseBelleville njengoko zingaboneleli ngoxinzelelo oluqhubekayo kwaye zingonakalisa isixhasi.

Amanqaku eNdibano:

1,Kuphephe ukusebenzisa i-TO isixhasi samandla kwiindibano ze-SMT.

I-2, iplastiki yokufakela izixhobo ezithambileyo okanye ezirhubuluzayo kumaqondo obushushu aphezulu kufuneka ziphetshwe

3, Musa ukuvumela intloko yesijivu ukuba ichukumise isichasi.Sebenzisa iiwasha ezicacileyo okanye iiwasha ezicoliweyo ukuze usasaze ngokulinganayo amandla

4, Zithintele izikrufu zentsimbi, ezidla ngokuqengqeleka imiphetho yemingxuma kwaye zenze iintsimbi ezitshabalalisayo kwiradiyetha.

I-5, iiRivets azikhuthazwa.Ukusebenzisa iirivets kunzima ukugcina uxinzelelo olungaguqukiyo kwaye kunokonakalisa ngokulula ukupakishwa kweplastiki

6,Musa ukuyigqithisa itorque.Ukuba i-screw iqinile kakhulu, ipakethe inokwaphuka ekupheleni kwe-screw (isiphelo sokukhokela) okanye ibe nomdla wokugobela phezulu.Izixhobo ze-pneumatic azikhuthazwa.

Ixesha lokuposa: Mar-14-2024